Detailed introduction of lining plate material for wet ball mill

2025-01-15 09:41:38

The liner plate of wet ball mill mainly plays two roles: one is to protect the cylinder of the ball mill and eliminate the direct friction and impact of materials and steel balls on the cylinder; Second, different types of ball mill liners can be used to adjust the movement state of the ball mill steel balls, enhance the crushing effect of the steel balls on materials, improve grinding efficiency, increase output and reduce metal consumption.

At present, the commonly used materials of the ball mill lining plate include high manganese steel lining plate, wear-resistant rubber lining plate, medium alloy lining plate, medium chromium lining plate, cast stone lining plate, etc. The following is a detailed introduction of three kinds of lining plates.

1、 Rubber lining plate

Advantages: light weight, lower labor intensity for installing lining plate, and shorter maintenance time; Light load, reduced power consumption, about 10% lower than other types of lining plates; The service life is long, and the service life of the barrel is extended, and the operation rate of the mill is improved; Save steel balls. If a concentrator with an annual output of 100000 tons can save about 150000 tons of steel balls compared with the manganese steel lining plate; The industrial noise is low and the operating conditions of workers are improved.

Disadvantages: not suitable for dry grinding, not resistant to high temperature, poor impact resistance, not suitable for the coarse grinding bin of ball mill.

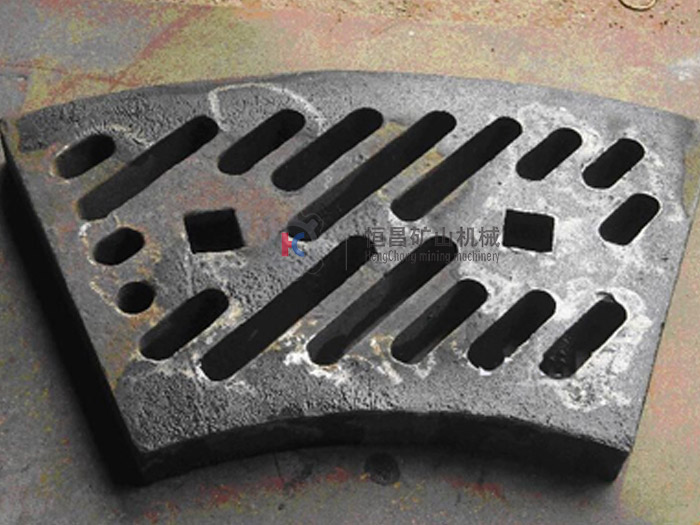

The rubber lining plate has many advantages and is widely used in the ball mill, including the cylinder rubber lifting strip, cylinder lining plate, feed end lining plate, discharge end grid plate and other parts of the ball mill. Of course, the rubber material of different parts will be different. At present, rubber lining is mainly used in wet grid type and wet overflow type ball mills.

2、 High manganese steel lining plate

Advantages: High manganese steel lining plate has a certain impact resistance toughness. When impacted, the surface will be hardened by cold work, hard and wear-resistant. The hardness can reach HB300-350, and the impact value can reach 700Nm/cm2.

Disadvantages: It is easy to reverse convex and bend and deform too early in use, and pull off the fixing bolts, causing the lining plate to fall off and reduce its service life. According to statistics, the service life of the high manganese steel lining plate is about 5000-6000 hours.

It is commonly used in the first bin of the ball mill – crushing bin. The particle size of the materials in the crushing bin is large, so the grinding body is required to be mainly impacted, and the grinding body should be in the state of throwing off. Therefore, the liner plate of the crushing bin must have a high lifting capacity for the grinding body and good impact resistance. The high manganese steel liner plate is the only choice to meet this requirement.

3、 High chromium cast iron lining plate

Advantages: excellent wear resistance and high temperature plasticity, high hardness, small hardness gradient, high tempering stability and corrosion resistance.

Disadvantages: poor impact toughness

High chromium cast iron lining plate is a lining plate material after high manganese steel. Compared with other wear-resistant materials, it has high hardness, and is superior in anti abrasive wear performance, especially under low load impact. However, due to high molybdenum content, high price, and limited application, many institutions are committed to improving the composition of high chromium cast iron to reduce costs.

At present, in addition to the above three kinds of mainstream lining plates, there are also stone lining plates, cast stone lining plates, and mixed lining plates used for the ball mill in the concentrator. However, the market is still dominated by high manganese steel, rubber, and high chromium cast iron, especially high manganese steel.