The main component of fluorite ore is calcium fluoride, which is an important raw material for the fluorine chemical industry. So what is the fluorite ore processing equipment? What is the processing plant? Fluorite ore has a specific gravity of 3.0-3.3 and good natural floatability. The mainly separation method is flotation and gravity separation. The flotation method is mainly used to produce high-quality chemical grade fluorite powder; the gravity separation method is mainly used to produce coarse-grained metallurgical grade fluorite concentrate.

Fluorite ore processing equipment:

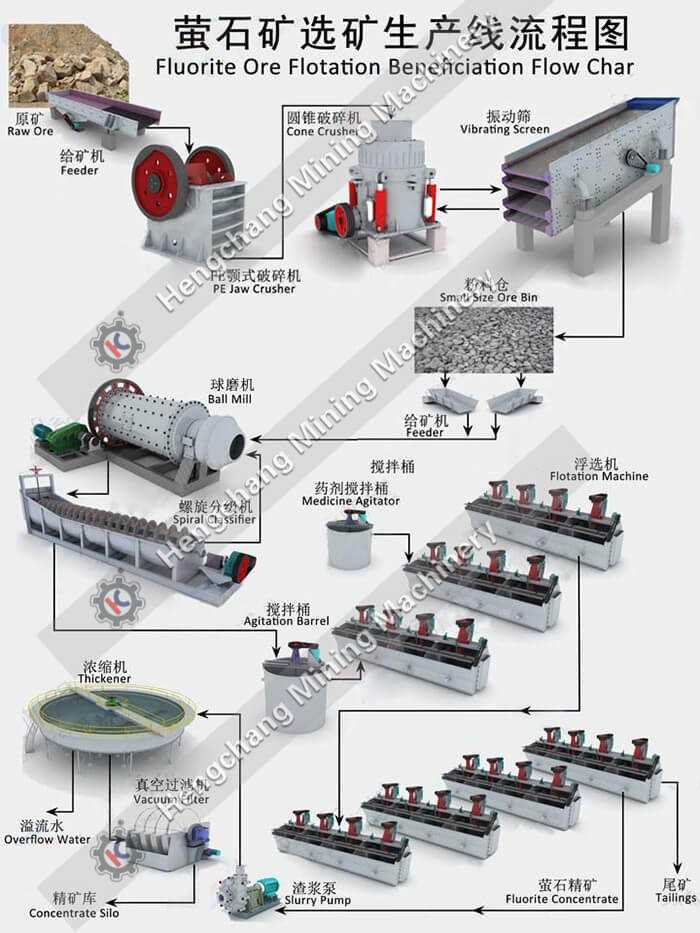

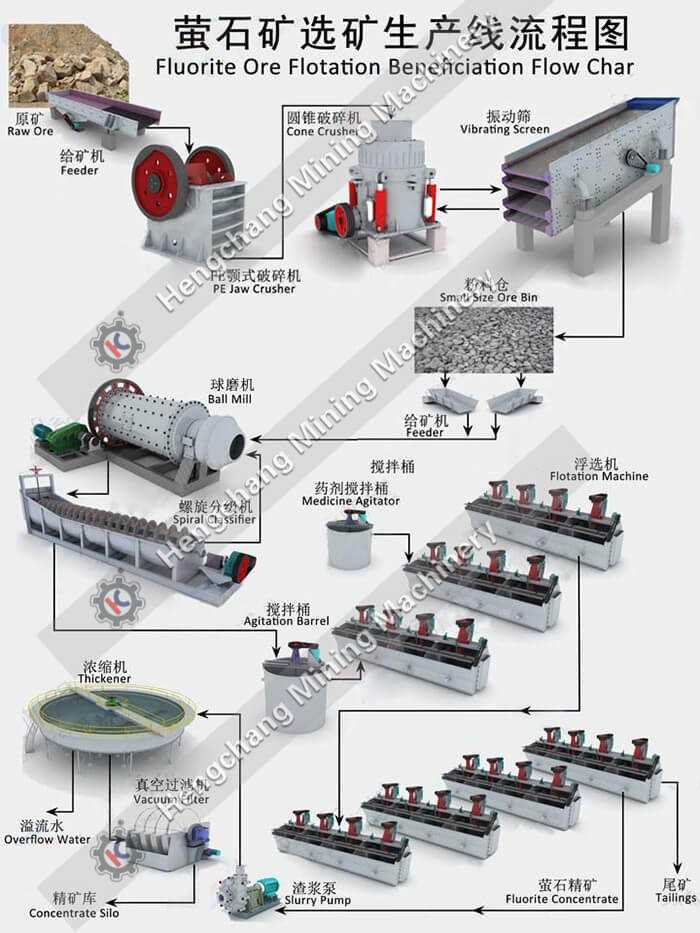

The fluorite ore processing production line has undergone stages of crushing, screening, grinding and classifying, gravity separation, flotation and drying. The main equipment include jaw crusher, ball mill, spiral classifier, jig machine, flotation machine, mixing tank, dryer, thickener, vibrating feeder, belt conveyor and other equipment. Among them, the flotation machine and jig machine are the key equipment in the fluorite ore processing plant, used to separate the fluorite concentrate.

Introduction of fluorite ore processing plant:

Fluorite is brittle and fragile. In the crushing process, hammer crusher or impact crusher should be used as little as possible; jaw crusher is mainly used for coarse crushing. The coarsely crushed materials enter the trammel screen, after the screen it will separate out 30+ mm, 0-8mm, 8-30mm three size materials, and the 30+ mm materials enter the manual belt conveyor for hand separation, manual separation is the process of manually separating fluorite lump ores by observing the difference between fluorite and waste rock. Due to the labor intensity of workers and unstable sorting indicators, manual separation has rarely been used. The ore is crushed until the jig is effectively put into the classifier for re-selection and purification. The 0-8mm and 8-30mm materials can be separated into trapezoidal jig machine and large particle jig machine, and the final concentrate is mixed with the hand-separated concentrate as a metallurgical-grade fluorite ore, the tailings enter the flotation process after dewatering.

The flotation process is divided into grinding, classifying, agitating, flotation and other processes. Due to the high requirements for concentrate grades, multiple flotation concentration separations more than 6 times, and the fluorite floatability is relatively good, usually only one scanning separation is required. Fluorite ore flotation adopts heating flotation; the main agents used are shale oil, oxidized paraffin soap and so on.

Fluorite ore is brittle and fragile. It is easy to produce many high-grade powdery ores during crushing, and there will be some loss in the process of gravity separation and manual separation. Therefore, the gravity separation and manual separation of fluorite ore tailings are often go to the flotation process to improve the concentrate grades. At the same time, the economic benefits are maximized.