Graphite ore can be divided into crystalline graphite, flake graphite and graphite ore with a variety of gangue. The graphite ore beneficiation process is mainly for the graphite ore with different crystal forms, such as graphite ore, pyrite or mica. It adopts multi-stage grinding multi-stage flotation and re-election flotation combined with two beneficiation processes.

Graphite is a kind of high-energy crystalline carbon material. Due to its unique structure and conductivity, thermal conductivity, lubrication, high temperature resistance and stable chemical properties, it has high application value in high performance materials. It is widely used in metallurgy, machinery, In the fields of environmental protection, chemical engineering, fire resistance, electronics, medicine, military industry and aerospace, it has become an indispensable non-metallic material for modern industry and the development of high, new and cutting-edge technologies.

The flotation method is a relatively common method for purifying minerals. Since the graphite surface is not easily wetted by water, it has good floatability and is easily separated from impurity minerals. The flotation of graphite ore is generally carried out by positive flotation followed by reverse flotation of the flotation concentrate. A higher grade graphite concentrate can be obtained by flotation. Flotation graphite concentrate grades can usually reach 80% to 90%, using multi-stage grinding; the purity can reach 98%. The commonly used collectors for flotation crystal graphite are kerosene, diesel oil, heavy oil, sulfonate, sulfate, phenol and carboxylate. The common foaming agents are 2# oil, 4# oil, pine oil, ether alcohol and Butyl ether oil, etc., the adjusting agent is lime and sodium carbonate, and the inhibitors are water glass and lime. The common collector for flotation of cryptocrystalline graphite is coal tar. Commonly used foaming agents are eucalyptus oil and pine oil. The commonly used regulator is sodium carbonate. The commonly used inhibitors are water glass and sodium fluorosilicate.

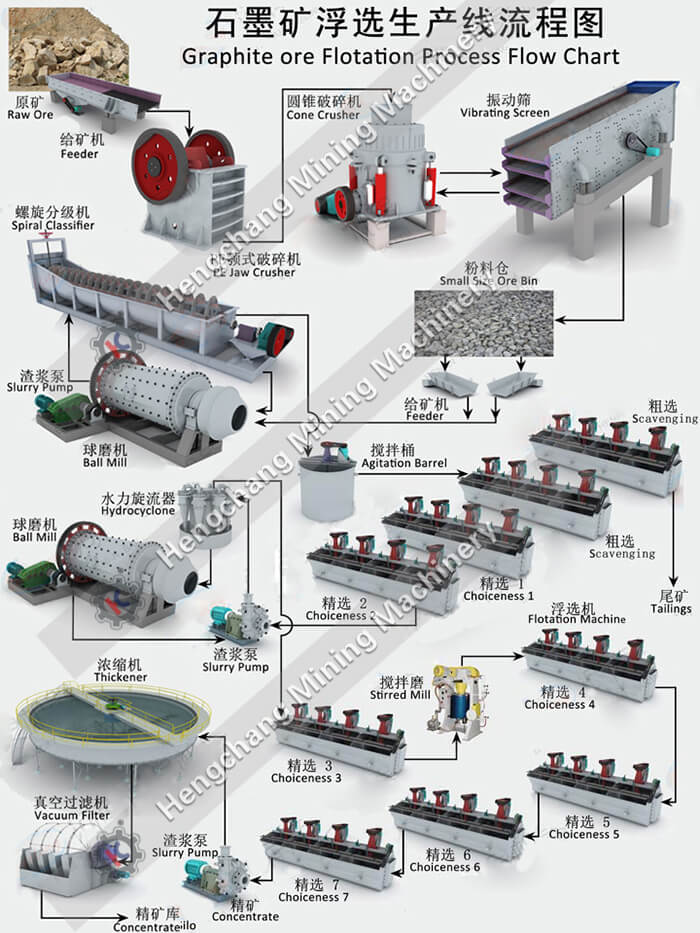

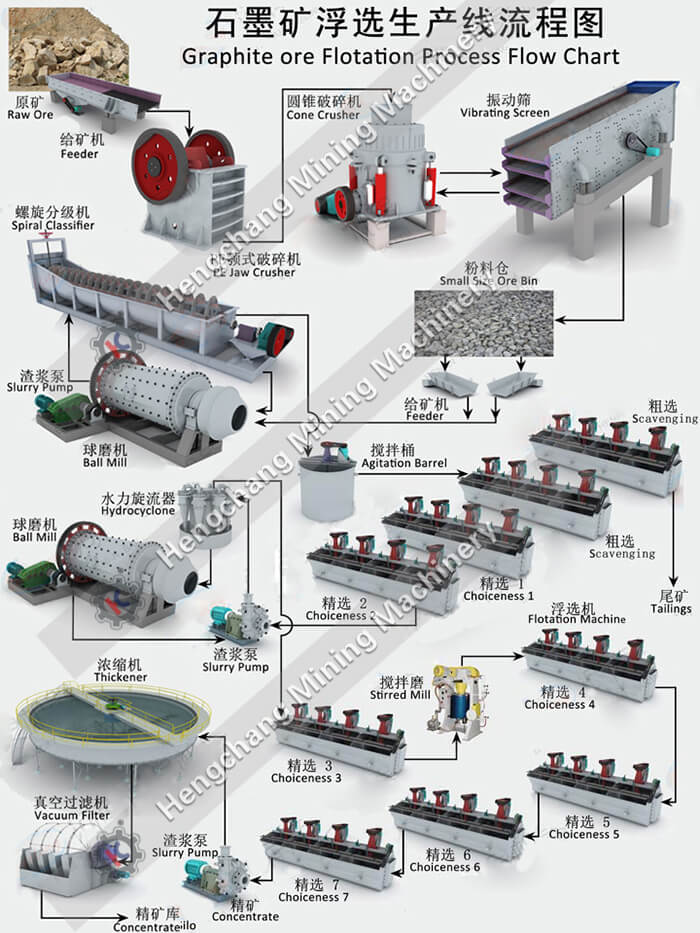

This graphite ore flotation plant including:

(1) Preparation processing: first and second crushing, and coarse milling.

(2) Flotation processing: rough separating, sweeping separating and fine separating.

(3) Concentrates treatment: dewatering, drying, screening and packing.

The raw ores are mainly flake graphite, gaugue minerals are calcite, chlorite, tremolite, plagioclase, garnet, kaolinite and etc. Flotation separation process with 4 stages of milling process and 5 times fine separating is adopted. The collecting agents are terpenol and triethoxy butane. Lime is used to adjust the PH value of the ore pulp to 8-9. In the raw ore, the grade is 4%-5%, but after this flotation separation process, the grade should be 89% and the recovery rate is about 80%. To get high purity graphite and high carbon graphite products, the fine concentrates should go through wet process chemical purification to reach the grade of 98%.

(4)Amorphous graphite ore beneficiation processing.

Amorphous graphite ores has high grade of 30%-90%, but due to the fineness of inserted graphite particles, it is difficult to improve the grade. Separating process is not needed when dealing with high grade graphite ore, and most graphite ores in China are with high grade. So the ore beneficiation process goes: raw ore-crushing process-milling process-flotation process-dewatering process-drying process-powder making process-classifying process and packing process. Cryptocrystalline graphite ore beneficiation process in Kayserberg, Austria includes the direct powder making dry process and flotation wet process. Its raw ores contains carbon of 30%-80%. In this flotation process, the coal oil is used as collecting agent, pain oil and flotation oil as foaming agent; PH value of ore pulp is 8, and the carbon content in the concentrates is 90%-92%; while the direct powder making dry process is for low carbon content graphite.