Lithium ore flotation process

2022-07-06 17:22:54

The beneficiation method of lithium ore is based on the mineral properties of lithium ore, mainly the physical, chemical or physicochemical properties of different minerals, using different methods to separate lithium ore and gangue minerals, and make the symbiotic useful minerals as much as possible. The separation process of separating from each other and removing or reducing harmful impurities to obtain the raw materials required for smelting lithium ore. It is a technological process between mining and smelting. After beneficiation of lithium ore, high-grade lithium ore concentrate can be obtained , so that mineral resources can be fully utilized.

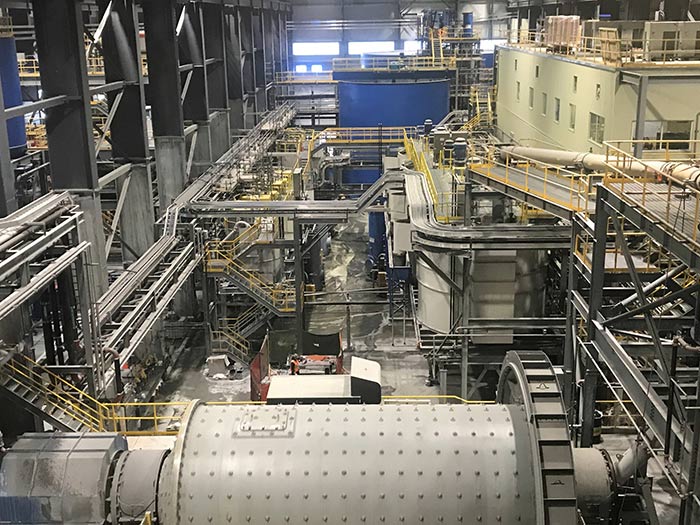

The process of the beneficiation method of lithium ore includes crushing, grinding, sorting and so on. Crushing is to turn large pieces of lithium ore or materials into small pieces to meet the requirements of the user department or the next process for the particle size of lithium ore products. According to the particle size of crushing, it can be divided into coarse crushing, medium crushing and fine crushing. Grinding is in mechanical equipment, with the help of media (steel balls, steel rods, gravel) and the impact and grinding action of the minerals themselves, so that lithium ore and gangue minerals can be dissociated to the maximum extent, so as to provide a particle size that conforms to the lower limit. Material required for a beneficiation process. Sorting, also known as lithium ore sorting or sorting, uses certain beneficiation methods to separate useful minerals, gangue minerals and different useful minerals in lithium ore from each other and enrich them separately. The sor ted products are lithium ore concentrate and lithium ore tailings.

In the beneficiation method of lithium ore, positive flotation is a frequently used method. After the first washing and desliming, add fatty acid (such as oleic acid) or its soaps as collectors for direct flotation of spodumene: after three selections, the grade of Li2O greater than 5% can be obtained, and the recovery rate is 70%~ 75% spodumene concentrate.

The beneficiation method of lithium ore – the introduction of the separation and enrichment method of beryl and spodumene: both spodumene and beryl are aluminosilicate minerals, often coexisting in the same pegmatite deposit; It is non-magnetic and has a relative density close to that of gangue minerals. Therefore, it is difficult to separate beryl and spodumene by magnetic separation and gravity separation, and only by flotation separation method. On the other hand, because garnet, amphibole, tourmaline, biotite and muscovite have similar floatability to beryl and spodumene, the enrichment and separation of beryl and spodumene are more difficult.

The flotation separation of beryl and spodumene generally includes mixed flotation and preferential flotation (preferential flotation of beryl, then spodumene, preferential flotation of spodumene, then beryl, or preferential flotation of part of lithium. Pyroxene, then lithium beryllium mixed selection and separation) two principle processes, cationic collectors and anionic collectors can be used for flotation.

The beneficiation method of lithium ore – the introduction of preferential flotation method: when cationic collectors are used, silicate minerals have relatively good floatability, so when separating beryl and spodumene, it is necessary to add regulators.

A. The beneficiation method of lithium ore gives priority to flotation of spodumene and then to beryl (spodumene is suppressed first, spodumene is preferentially flotated, then beryl is activated and flotation is carried out). Sodium fluoride and lignosulfonate inhibit beryl and gangue; lignosulfonate forms a hydrophilic film on the surface of beryl and gangue minerals, preventing the attachment and adsorption. However, the effect of lignosulfonate on spodumene mineral particles is relatively small, so the preferential flotation of spodumene can be guaranteed. For example, in a low-alkali medium , adding sodium carbonate-alkali lignin (using alkali to dissolve lignosulfonate) into a ball mill and acting for a long time, at this time, beryl and gangue minerals are inhibited, and oxidized paraffin soap, naphthenic Acid soap and diesel flotation spodumene. The flotation tailings use sodium hydroxide, sulfate and ferric chloride to activate beryl and inhibit sodium gangue, and also use oxysome d paraffin soap and diesel to flotate beryl.

B. The beneficiation method of lithium ore gives priority to flotation of beryl and then to spodumene (spodumene is inhibited first, beryl is preferentially flotated, and spodumene is reactivated and flotation is carried out) to first remove free-floating minerals, and then in hydrogen Inhibition of spodumene in highly alkaline media conditioned by sodium oxide, sodium sulfide and sodium carbonate, flotation of beryl with fatty acids (such as oxidized paraffin soap and diesel); paraffin soap and diesel) flotation of spodumene. The beneficiation method of lithium ore When an anionic collector is used, the descending order of the inhibitor to spodumene is: sodium fluoride, lignosulfonate, phosphate, sodium carbonate, sodium fluorosilicate, sodium silicate, The inhibitory effect of these modifiers on beryl varies greatly. In neutral and weak alkaline media, a large amount (more than 1 kg/ton) of sodium fluoride, lignosulfonate, phosphate, carbonic acid Salt and so on have a strong inhibitory effect, while a small amount of sodium silicate, starch, etc. have no obvious inhibitory effect on beryl. In strong alkaline medium, the inhibitory effect of these agents is generally weakened, but the inhibitory effect of spodumene is generally enhanced.

C. The beneficiation method of lithium ore gives priority to flotation of part of lithium, and then to mix and separate lithium beryllium? Sodium fluoride and sodium carbonate are used as regulators and added to a ball mill, and fatty acid soap is used to preferentially flotate part of spodumene. Add sodium hydroxide and calcium ions to the ore for activation, and then use fatty acid soap to mix flotation spodumene-beryl, and use sodium carbonate, sodium hydroxide and acid, alkaline water glass to heat the mixed coarse concentrate (for example, 85 ° C ) processing, the beryl concentrate emerges.

The beneficiation method of lithium ore The reverse flotation operation process is carried out in alkaline pulp, dextrin, starch, etc. are used as inhibitors of spodumene, terpineol oil is used as foaming agent, and amine cationic collector is used to flotate quartz , feldspar and mica and other gangue minerals, after the iron is removed from the product in the tank, it is spodumene.

Lithium extraction from lithium ore is one of the earliest methods used, and it has now developed more maturely. At present, the main mature spodumene beneficiation processes include hand selection-magnetic separation process, flotation magnetic separation process, flotation, gravity separation, magnetic separation combined process, mineral processing-chemical treatment combined process, and beneficiation-metallurgical combined process. Each process has its own characteristics, and it can be selected according to the composition and properties of the lithium deposit and the main products.

Lithium ore beneficiation is an important part of the comprehensive utilization of mineral resources, and an important way for mines to increase production, reduce costs and improve product quality. Only by adopting beneficiation methods suitable for lithium ore for the specific properties of different minerals can the ore be fully utilized. Based on the main principle of improving efficiency and reducing costs, staff should vigorously develop mineral processing technology, and continuously improve the level of mineral processing industry and mineral processing technology, so as to better meet the needs of domestic and foreign markets.