Common problems and solutions of 6s shaking table

2022-09-15 13:56:28

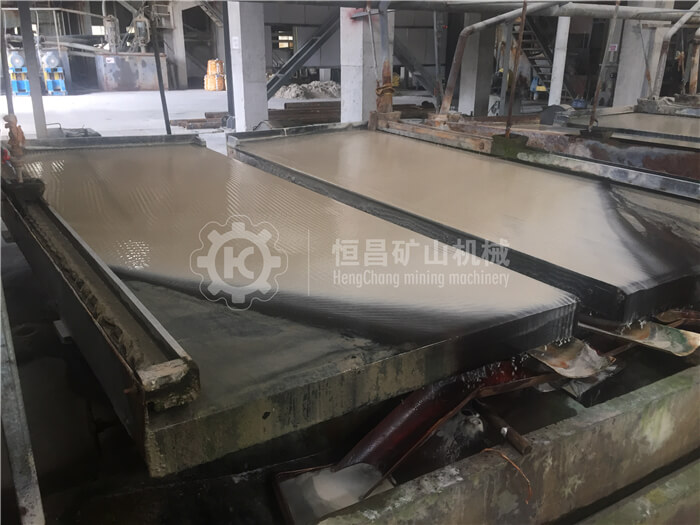

6S-Shaking table is one of the essential equipment for the gravity beneficiation process. Although the price is not high, it is very common, but if there is a problem, it will seriously affect the smooth progress of the gravity separation process. Therefore, the common problems and solutions of the 6S shaking table are still It is necessary to know in details.

1.Large pulley: Stop the machine to check and turn the large pulley by hand. If you feel that there is a gap in the large pulley, it means that the large pulley is not installed properly, which is very likely to produce abnormal noise in actual production.

Solution: Find a discarded hacksaw skin or a thinner piece of iron, stuff it into the key of the large pulley (commonly known as a pin), then tighten the fixing screw next to it, and then check whether the gap is eliminated.

2.Rocking lever: stop inspection, first remove the two toggle plates next to it, stabilize the large pulley with one hand, and swing the rocking lever with the other hand. If it cannot swing, if it is on the contrary, it means that the rocker is not fixed, which is not easy to produce abnormal noise in production.

Solution: Tighten the fixing screw on the rocker of the 6s shaker.

3.Spring: stop the machine and check to see if the spring is out of position.

Solution: Hit the spring with a hammer to force the spring back.

4.Eccentric shaft: It is also a shutdown inspection. Hold the large pulley with both hands and swing it back and forth. If it feels active or there is a mechanical gap, it means that the eccentric shaft of the 6s shaker is not fixed properly.

Solution: Tighten the two small screws on the transmission case oil seal cover.

5.Toggle plate: Start the inspection, touch the two toggle plates with the thumb and middle finger of one hand, and feel whether there is a gap.

Solution: Adjust the screw on the spring screw according to the actual clearance.

6.For the four support plates on the saddle footing: stop and check to see if the four support plates are in the correct position, such as whether they are in the middle of the shaking box, and check whether they will scrape the side walls of the shaking box.

Solution: Adjust the position of the support plate so that it is in the correct position.

The 6s shaking table has a simple structure, low price and high sorting efficiency. It has become one of the essential equipment in the current re-selection process. If you have enough understanding of its structure and common problems, you can save maintenance time and start construction as soon as possible to avoid waste.