What is the grinding fineness control for ball mill?

2025-12-08 11:22:24

There is no fixed standard value for the grinding fineness of a ball mill. It needs to be determined comprehensively based on factors such as ore properties, beneficiation process requirements (e.g., flotation, magnetic separation, gravity separation), and subsequent processing flows. The following are reference ranges and key influencing factors for common scenarios:

I. Core Concept: Methods of Expressing Grinding Fineness

It is usually expressed as the yield percentage of -200 mesh (-0.074 mm) (i.e., the percentage of particles smaller than 0.074 mm by mass of the total material). Some processes may also use requirements for -325 mesh (-0.045 mm) or specific particle sizes (e.g., +100 mesh, -400 mesh).

II. Typical Grinding Fineness Ranges for Different Beneficiation Processes

1. Flotation Process (Most Common)

Flotation requires a high degree of liberation of individual minerals, necessitating adjustments based on the mineral dispersal particle size:

• Coarse-grained dispersive ores (e.g., some iron and copper ores): -200 mesh 60%~75%;

• Medium-fine-grained dispersive ores (e.g., most gold, lead-zinc, and molybdenum ores): -200 mesh 75%~85%, or even over 90%;

• Very fine-grained dispersive ores or difficult-to-beneficiate ores (e.g., some oxide ores, complex polymetallic ores): -200 mesh can reach 90%~95%, or may need to be mixed with -325 mesh (e.g., -325 mesh 70%~80%).

2. Magnetic Separation Process (Strongly Magnetic Minerals/Weakly Magnetic Minerals)

• Strongly magnetic minerals (e.g., magnetite): Avoid over-grinding, which weakens magnetic agglomeration or causes mud formation. Typically, -200 mesh should comprise 50%~65% (coarse grinding is sufficient for individual mineral liberation).

• Weakly magnetic minerals (e.g., hematite, limonite, requiring roasting or reverse flotation): If roasting followed by magnetic separation, the -200 mesh can be slightly coarser (55%~70%); if direct reverse flotation is used, fine grinding to 75%~85% of the -200 mesh is required.

3. Gravity Separation Processes (e.g., Nelson mills for gold ore, shaking tables for tungsten-tin ore)

Gravity separation relies on particle density and size differences. Over-grinding leads to the loss of fine particles:

• Coarse-grained gravity separation (e.g., +74μm dominant): -200 mesh 30%~50%;

• Fine-grained gravity separation (e.g., fine-grained disseminated gold ore): -200 mesh 60%~75%, but excessive fineness must be avoided (to prevent mud encapsulation).

4. Cyanide Leaching Processes (Heap Leaching/Carbon Leaching for Gold Ore)

Heap leaching typically involves coarse grinding (-200 mesh 20%~40%) because the leachate has difficulty penetrating fine particles; carbon leaching (CIL) requires fine grinding to -200 mesh 70%~85% to ensure gold particle exposure.

III. Key Factors Affecting Grinding Fineness

1. Ore Dispersion Characteristics: The finer the mineral crystal size, the finer the grinding required (e.g., finely disseminated gold ore must be finely ground);

2. Beneficiation Requirements: Higher concentrate grade and recovery rate requirements often necessitate finer grinding (e.g., achieving a gold recovery rate >95% requires grinding to -200 mesh or higher);

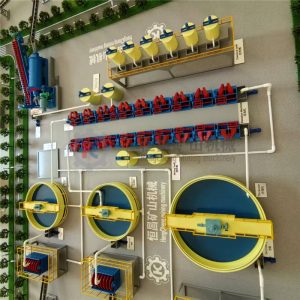

3. Grinding Equipment and Process: Closed-circuit grinding (with classifier/cyclone separator) is easier to stabilize fineness than open-circuit grinding; rod mills are commonly used for coarse grinding, while ball mills are used for fine grinding;

4. Energy Consumption Balance: Excessively fine grinding significantly increases power consumption (grinding energy consumption is exponentially related to fineness), requiring a trade-off between “liberation degree” and “energy consumption.”

Summary

Ball mill grinding fineness requires customized design, with a typical range of -200 mesh 50%~95%. Specific values need to be determined based on ore process mineralogical studies and beneficiation experiments. During production, parameters such as mill speed, ball loading, feed rate, and classifier return sand rate are adjusted to stabilize fineness and ensure optimal separation performance.