The Jaw Plate Material of Jaw Crusher for Crushing Stage

2026-01-08 16:51:47

The Jaw Plate Material of Jaw Crusher for Crushing Stage

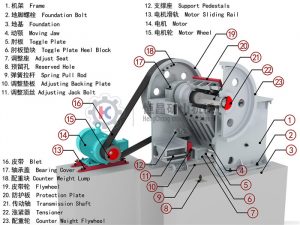

In a jaw crusher, the moving jaw plate is connected to the eccentric shaft at the top and supported by the thrust plate at the bottom, while the fixed jaw plate is fixed to the frame. When the eccentric shaft rotates, the moving jaw plate mainly bears the compressive force of the material, while the fixed jaw plate mainly bears the sliding cutting force. As a component with a high wear rate in jaw crushers, the choice of jaw plate material directly affects the user’s cost and efficiency.

High manganese steel is a traditional material for jaw crusher jaw plates, offering excellent resistance to impact loads. However, due to the crusher’s structure, the angle between the moving and fixed jaw plates is too large, easily causing abrasive slippage. Insufficient strain hardening results in low surface hardness of the jaw plates, leading to short-stroke abrasive cutting and rapid wear.

To improve the service life of jaw plates, various jaw plate materials have been developed, such as modifying high-manganese steel by adding elements like Cr, Mo, W, Ti, V, and Nb, and subjecting high-manganese steel to dispersion strengthening treatment to improve its initial hardness and yield strength. In addition, medium-manganese steel, low-alloy steel, and composites of high-chromium cast iron and high-manganese steel have also been developed, all of which have achieved good results in production.