HOME

>

NEW CENTER

>

New Arrival Mineral Processing Equipment Dry Roller Magnetic Separator for Ilmenite Ore

HOME

>

NEW CENTER

>

New Arrival Mineral Processing Equipment Dry Roller Magnetic Separator for Ilmenite Ore

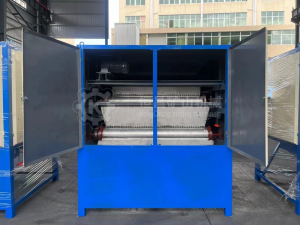

New Arrival Mineral Processing Equipment Dry Roller Magnetic Separator for Ilmenite Ore

2025-05-27 16:20:53

There are one roller, two rollers, three rollers, four rollers dry type high intensity magnetic separator and low intensity magnetic separator, magnetic field intensity from 800 gauss to 20000 gauss. the dry magnetic separators are widely used for separate magnetic iron ore, Tin ore, ilmenite, titanium ore, hematile, manganese, cobalt, cassiterite, coltan,tantalum, niobium, zircon sand, beach black sands, Monazite ore, Rutile ore,silica purify sand and so on.

How to use the roller magnetic separator?

1. This dry roller magnetic separator machine is used to sort a variety of magnetic mixed minerals with a particle size of 0-2mm. On the basis of the feasibility of magnetic separation, the iron is removed by a first-stage magnetic roller and the design of the strong magnetic roller is divided into sections. A variety of magnetic mixed minerals are selected. This machine is classified as a downstream structure according to the movement direction of the magnetic product and the incoming mineral to be selected. Pick and choose. The ore grade of this machine is two grades of concentrate and tailings.

2. The machine adopts the multi-stage selection design of permanent magnet magnetic system, and the work is stable, and the concentrate grade can be guaranteed even when the processing capacity is large.

3. The machine has compact structure, small volume, light weight, high efficiency, low power consumption, and is very beneficial to maintenance and repair.

4. The transmission principle of this machine is also very simple, the operation is convenient and simple, and the work efficiency is also very high.

5. The machine incorporates advanced electrical control technology, which makes the production operation convenient and easy to understand, and reduces the operator’s labor intensity while improving work efficiency.

6. There is an adjustable partition plate in the sorting bucket of this machine. The main trough, material guide trough and partition plate are all made of high wear-resistant stainless steel, which can effectively ensure the service life of the machine and avoid rust affecting the quality of minerals. Possibly; the dividing plate can be flexibly adjusted and fast fixed, which plays a great role in ensuring the quality of the ore position during the production process.

7. The electromagnetic speed-regulating motor is used to provide power to ensure the service life of the motor and the mechanical transmission power; the speed of ore dressing can be adjusted, and the multi-stage minerality can be sorted.