Methods to Extend the Life of Jaw Plates in Jaw Crusher

2026-01-09 09:27:25

Methods to Extend the Life of Jaw Plates in Jaw Crushers

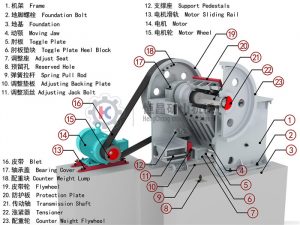

Jaw plates, consisting of fixed and movable jaw plates, are wear-resistant components of jaw crushers. During operation, the movable jaw, attached to the movable jaw plate, performs a pendulum motion, forming an angle with the fixed jaw plate to compress the stone. Therefore, jaw plates are among the most easily damaged parts of a jaw crusher.

I. The Reasons of Jaw Plate Wear

1. Uneven contact between the jaw plate and the machine surface;

2. Excessive eccentric shaft speed, preventing the timely removal of crushed material, leading to blockage of the crushing chamber and jaw plate wear;

3. Changes in material properties without timely adjustment by the crusher;

4. An excessively large angle between the movable and fixed jaw plates, exceeding the normal range;

5. Poor inherent strength, wear resistance, and impact resistance of the jaw plates.

II. Solutions

1. When installing the jaw plates, ensure they are properly installed and securely fixed to ensure stable contact with the machine surface.

2. A layer of highly ductile material can be placed between the jaw plates and the machine surface.

3. Each batch of material entering the crusher should be randomly inspected. If significant changes in material properties are found, the crusher parameters should be adjusted promptly to match the incoming material.

4. Jaw plates must be made of high-hardness, wear-resistant, and impact-resistant materials, commonly high-manganese steel.

5. Cement companies with ore crushing production line technology can interchange worn jaw plates of the same type for both ore coarse crushing and cement fine crushing. Worn jaw plates can be repaired using welding.