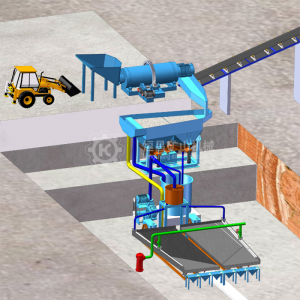

How to Use the Gravity Separation Equipment Jig Separator for Gold Mining Processing?

In the field of gravity mineral processing, the jig separator is very popular and important. Wide selection of particle size, simple operation and maintenance, mainly used in the gold, tungsten ore, tin ore, hematite and seaside placer.

Working Principle of the Jig Machine

The core separation principle of the jig is to utilize the difference in specific gravity between minerals to achieve separation under the action of water flow in a deep trough. The sorting tank of a jig is deeper than that of ordinary separation equipment. During operation, the water flow performs an up-and-down pulsating motion within the sorting tank. When the water flows upward, it carries the mineral particles in the slurry upwards together; when the water flows downward, the mineral particles sink under the influence of gravity.

Because different minerals have varying specific gravities, their settling speeds also differ. Mineral particles with higher specific gravity settle faster and gradually accumulate at the bottom of the sorting tank, forming the concentrate. In contrast, gangue minerals with lower specific gravity settle more slowly, remaining in the upper layer of the slurry and being carried away by the water flow, thus becoming tailings. In this way, the separation of valuable minerals from gangue is achieved.

Because different minerals have varying specific gravities, their settling speeds also differ. Mineral particles with higher specific gravity settle faster and gradually accumulate at the bottom of the sorting tank, forming the concentrate. In contrast, gangue minerals with lower specific gravity settle more slowly, remaining in the upper layer of the slurry and being carried away by the water flow, thus becoming tailings. In this way, the separation of valuable minerals from gangue is achieved.

HOME

>

NEW CENTER

>

How to Use the Gravity Separation Equipment Jig Separator for Gold Mining Processing?

HOME

>

NEW CENTER

>

How to Use the Gravity Separation Equipment Jig Separator for Gold Mining Processing?