Advantages of Ball Mills over Wet Pan Mills for Grinding Gold Ore

2025-12-03 10:39:20

Ball mill is the mainstream core equipment in modern, large-scale, high-efficiency gold beneficiation plant, while wet pan mill is more suitable for small-scale, simple, or specific gold beneficiation operation. Compared to wet pan mill, ball mill has the following main advantages:

I. Differences in Core Working Principles (The Root of Advantages)

Ball Mill: Employs a combined impact and grinding action. The cylinder contains steel balls. When the cylinder rotates, the steel balls are lifted to a certain height and then fall, impacting the ore like projectiles. Simultaneously, the steel balls roll and slide against each other and against the liner, finely grinding the ore. This is a continuous and efficient crushing process.

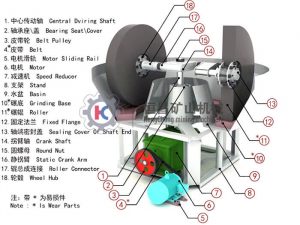

Wet Pan Mill: Employs a compression and kneading action. It mainly uses heavy grinding wheels to crush the ore on a grinding disc, utilizing enormous static pressure to break and finely grind the ore. Its crushing efficiency is relatively low, and there is a risk of over-crushing and mudding.

II. Core Advantages of Ball Mills

1. High Crushing Efficiency and Large Processing Capacity

Ball mills: Through the vigorous movement of steel balls, ball mills can crush ore to a very fine particle size (typically above 200 mesh) in a short time, with a processing capacity far exceeding that of gold mills per unit time. This makes them ideal for large-scale industrial production, capable of processing hundreds or thousands of tons of ore per day.

Comparison: Gold mills rely on the slow crushing force of the grinding wheels, resulting in low efficiency and small processing capacity, suitable only for small workshops or experimental production with a daily processing capacity of less than tens of tons.

2. Uniform Product Particle Size and Strong Controllability

Ball mills: By adjusting parameters such as the ball-to-material ratio, rotation speed, and ball size distribution, the final output particle size can be precisely controlled. The product particle size distribution is relatively concentrated, with a high content of fine particles, which is beneficial for subsequent gold extraction processes such as flotation or cyanide leaching, significantly improving gold recovery rates.

Comparison: Wet pan mills produce uneven particle sizes, easily generating a large number of unacceptable coarse particles and over-crushed, muddy fine particles. This unevenness severely affects subsequent beneficiation effects and reduces recovery rates.

3. High adaptability, capable of handling various ores

Ball mills: Can handle ores of various hardnesses, effectively crushing from soft to extremely hard ores. Their adaptability is very wide by changing the grinding media and operating parameters.

Comparison: Wet pan mills are mainly suitable for ores of medium to low hardness and relatively loose structure. For hard, dense gold ores, their crushing efficiency is low, energy consumption is high, and wear is severe.

III. Disadvantages of Ball Mills (as a Balancing Reference)

Of course, ball mills are not without their drawbacks. Their main disadvantages are:

1. high investment costs: the equipment itself and its associated motors, reducers, etc., are expensive.

2. High energy consumption: Compared to some new energy-saving mills (such as vertical mills), traditional ball mills consume significantly more energy.

3. Noise and dust generation: Requires robust environmental protection measures.

For certain gold mines (such as oxide ores with extremely high mud content), using a ball mill alone may exacerbate mud formation problems; sometimes it needs to be used in conjunction with classification equipment.